Built-in Motor Spindle with Housing Diameter 150 Manufacturer | MicroLab Precision Technology Co., Ltd.

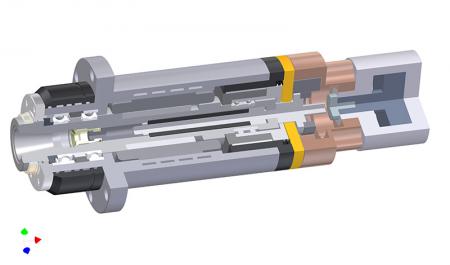

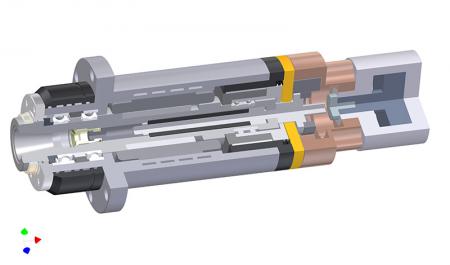

Built-in Motor Spindle with housing diameter 150 is High torque and high speed machining spindles. There are 3 types for Built-in Motor spindle with housing diameter 150, M4-RMSC / H6-RMSC and M4-JMRC. M4-RMSC, tool holder optional is BT40 / DIN40 / CAT40 / BBT40, Flanged type, hydraulic tool exchanging. H6-RMSC, tool holder is HSK63A, Flanged type, hydraulic tool exchanging. M4-JMRC, tool holder optional is BT40 / DIN40 / CAT40 / BBT40, Flanged type, hydraulic tool exchanging.

Built-in Motor Spindle with Housing Diameter 150

Built-in Motor Spindle with housing diameter 150 is High torque and high speed machining spindles.

There are 3 types for Built-in Motor spindle with housing diameter 150, M4-RMSC / H6-RMSC and M4-JMRC.

M4-RMSC, tool holder optional is BT40 / DIN40 / CAT40 / BBT40, Flanged type, hydraulic tool exchanging.

H6-RMSC, tool holder is HSK63A, Flanged type, hydraulic tool exchanging.

M4-JMRC, tool holder optional is BT40 / DIN40 / CAT40 / BBT40, Flanged type, hydraulic tool exchanging.

For this spindle type, every spindle has a water repellant ring to effectively repel any cutting fluids away from the spindle to prevent anything from splashing into the labyrinth area during high speed cutting.

During high speed operation, positive air pressure coming out from the labyrinth prevents any contamination from entering into the spindle.

The compactly designed helical cooling channels effectively dissipate heat from the stator coil and bearings to reduce the effects of thermal deformation on precision.

During acceleration and deceleration of the spindle, the patented gripper guide ring design eliminates any unusual noises and vibration of dynamic balance.

Every spacer is inspected for precision to assure unanimous quality of every spindle.

Suitable for clean room operation, the PCB model type is made with stainless steel to allow the use of a water cooling system.

After heat treatment, the critical parts undergo a hardness test to ensure they have the correct hardness in order to reduce their risk of damage during operation.

To effectively decrease vibration, we conduct dynamic balancing calibration at 3 different planes.

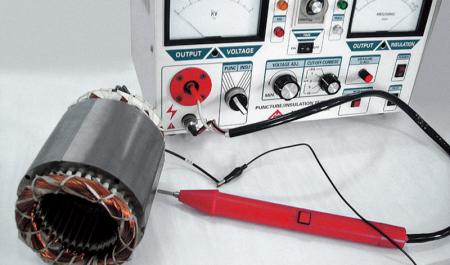

Testing the isolation grade of the stator coil ensures stable electronic drive control and long operational life.

Built-in Motor High Speed Spindle with Housing diameter 150

M4-RMSC, H6-RMSC, M4-JMRC

M4-RMSC and M4-JMRC, Built-in Motor Spindle with Housing diameter 150, which are the high speed...

DetailsMachining Center Spindle, Built-in Motor Spindle with Housing Diameter 150 Manufacturer - MicroLab

Located in Taiwan since 1999, MicroLab Precision Technology Co., Ltd. is a machining spindle manufacturer in Machine Tool Industry. Main products, including Machining Center Spindle, Built in Spindle, Rotary Spindle Head, A/C Double Rotary Spindle Head, Direct Drive Spindle, High Speed Spindle, Pulley Driven Spindle and so forth.

High efficacy spindles & rotary table manufacturing with deep background of Science & Technology to transcend the best performance and safety of products according to the international inspection and evaluation. Milling & turning direct drive spindle, direct drive spindle, built-in motor spindle, direct drive spindle and pulley driven spindle with outstanding characteristics in regards to bearings, speed suitability and machining.

MicroLab has been offering customers high-quality machining spindles, both with advanced technology and 30 years of experience, MicroLab ensures each customer's demands are met.